Uptime Protection for mission critical sites

Measure where it matters.

Vigilent monitors the most critical environmental metric of your IT infrastructure, the rack inlet temperature, every minute to ensure your facility is not headed toward heat-related downtime.

That’s essential, because uptime is critical for a data center – every minute of downtime can mean that orders don’t get booked, calls are missed, potential clients move on to other suppliers, or worse. Downtime brings with it a very real cost and, depending on the nature of your business, this cost may range from thousands to hundreds of thousands of dollars of lost opportunity or lost revenues each hour.

Data Center Knowledge reports that the average cost per minute of unplanned downtime is $7,900, up 41 percent from $5,600 per minute in 2010. Of the 584 data centers surveyed, 91 percent experienced an unplanned outage in the past two years, with an average downtime length of 86 minutes, which makes $690,200 the average cost of a downtime incident.

Uptime from the ground up

Our system was designed for mission critical facilities around the world.

Every point in the Vigilent system is architected with uptime in mind.

Before we install a system at your facility, the components are built and tested in advance. This ensures we can identify and fix any issues before the system is shipped, unlike a BMS that is field programmed and saves the troubleshooting for the commissioning phase. This not only reduces our install time, but also makes our algorithm more reliable than traditional control schemes.

Vigilent system analytics help ensure uptime by providing real-time operational information about cooling unit performance. By tracking declining system performance on the trends screen, you can identify broken units before they fail. Through the user interface, you can identify racks without any operational cooling redundancy on the facility floor, as well as help prevent maintenance-related failures by showing the impact of taking a cooling unit offline.

And our failsafe procedures trigger the facility to receive the maximum amount of cooling if anything goes wrong, so that your facility keeps running.

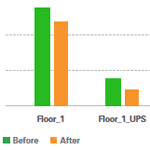

Eliminate hot spots

The system typically identifies and automatically alleviates up to 95 percent of hot spots. We can achieve these impressive results by delivering the right mix of cooling exactly where it’s needed.

Often times, competing cooling units can result in an area getting hotter, not cooler. Our system models the airflow in your facility to learn the influence of every cooling unit on the thermal environment.

By eliminating the vast majority of hotspots, our system helps you to identify any remaining hotspots that need special attention to be resolved, through means such as rearranging perforated tiles or removing airflow obstructions.